CCAD-Stair

CCAD-Stair is the module for editing precast concrete stairs. It plans not only straight or spiral stairs, but also complete staircases in combination with the respective wall and ceiling modules. Staircases can be planned both individually as well as within a building module, with consideration given for connection conditions on landings, ceilings, walls or beams.

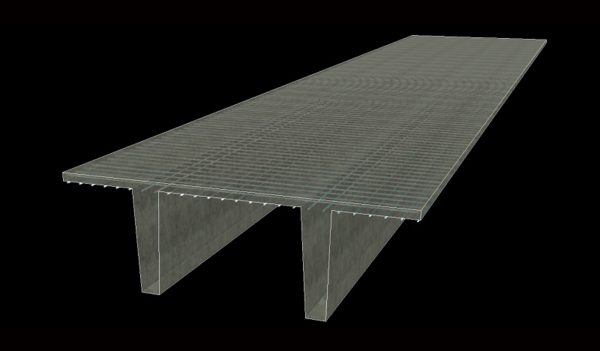

Straight stairs:

To begin with, only the basic data such as stair width and height needs to be entered. The program will automatically suggest a default staircase, which can then be edited directly and adjusted to the required parameters (number of gradients, rise-to-run ratio, head height/foot length etc.). The results can be checked visually at any time in a 3D viewer.

If the stairs are generated as free-standing and not connected to an existing ceiling or landing, only the width of the staircase needs to be specified. The program then calculates the required height. In this case, the required connection details such as brackets, including reinforcements, are generated automatically.

The program monitors compliance with certain parameters throughout the planning process. For instance, the rise-to-run ratio can only be changed within certain logical areas.

Winding Stairs

In this case, in addition to the stair width and height, the type (quarter spiral, half spiral or double spiral) must be indicated. Details of flange lengths must also be specified.

The stairs can be completely reinforced using predefined reinforcement types. Three independent areas (foot of the stairs, stair flight, and stairhead) are available here. The program can also process 3D curved reinforcement positions (stair rods in the case of spiral staircases).

Staircases

A practical function is available here: Firstly, the number and height of the floors are defined on the basis of the project data. The program then automatically draws multiple views of the staircase to provide the planner with an excellent overview. The landings and stairs are subsequently positioned in succession in the staircase. The standard stair input dialog is again available for this purpose. The program automatically monitors to ensure compliance with the points of intersection between various flights of stairs and/or landings. This guarantees, for example, that the underside of the stairs is at the same height as the underside of the connecting landing. Once planning has been completed, the user can automatically generate production plans for the flights of stairs and layout plans for the staircases.